Special casters for secondary battery and aerospace industry

Page info.

Writer : G-DOK Industrie… Date : 2023-07-24 View : 865Content

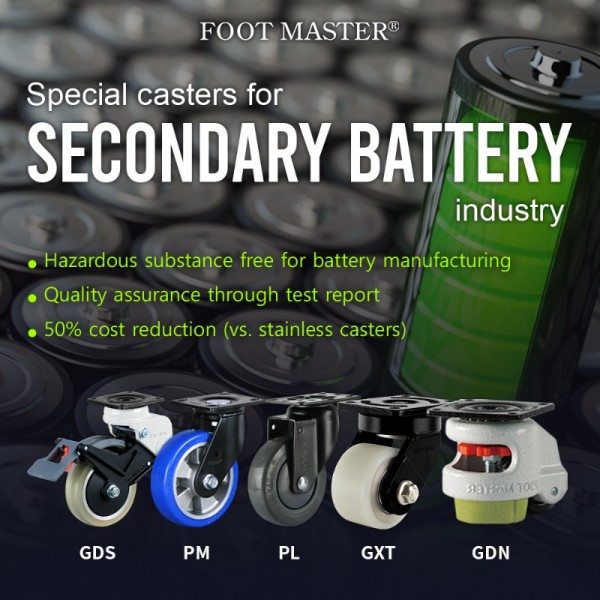

G-DOK has released special casters exclusively for the secondary battery and aerospace industry.

Hazardous materials for the battery industry have been removed, and the performance and quality are top-notch casters.

What is the difference between casters for secondary batteries and batteries?

The battery industry strictly regulates substances that can be problematic in the manufacturing process. This is because it can lead to the risk of battery explosion later. The casters used in the market contain many substances that can be hazardous in the battery industry.

Stainless casters or electroless nickel casters are suggested as alternatives for the secondary battery industry, but the price is very expensive and the caster types are very limited. As a result, customers were often unable to find high-end premium casters in the market.

Accordingly, G-DOK has released battery industry casters exclusively for secondary batteries.

As the world's first casters specialized for the battery industry, they are premium casters designed for the development of the secondary battery industry around the world.

What kind of casters are there specifically for secondary battery casters?

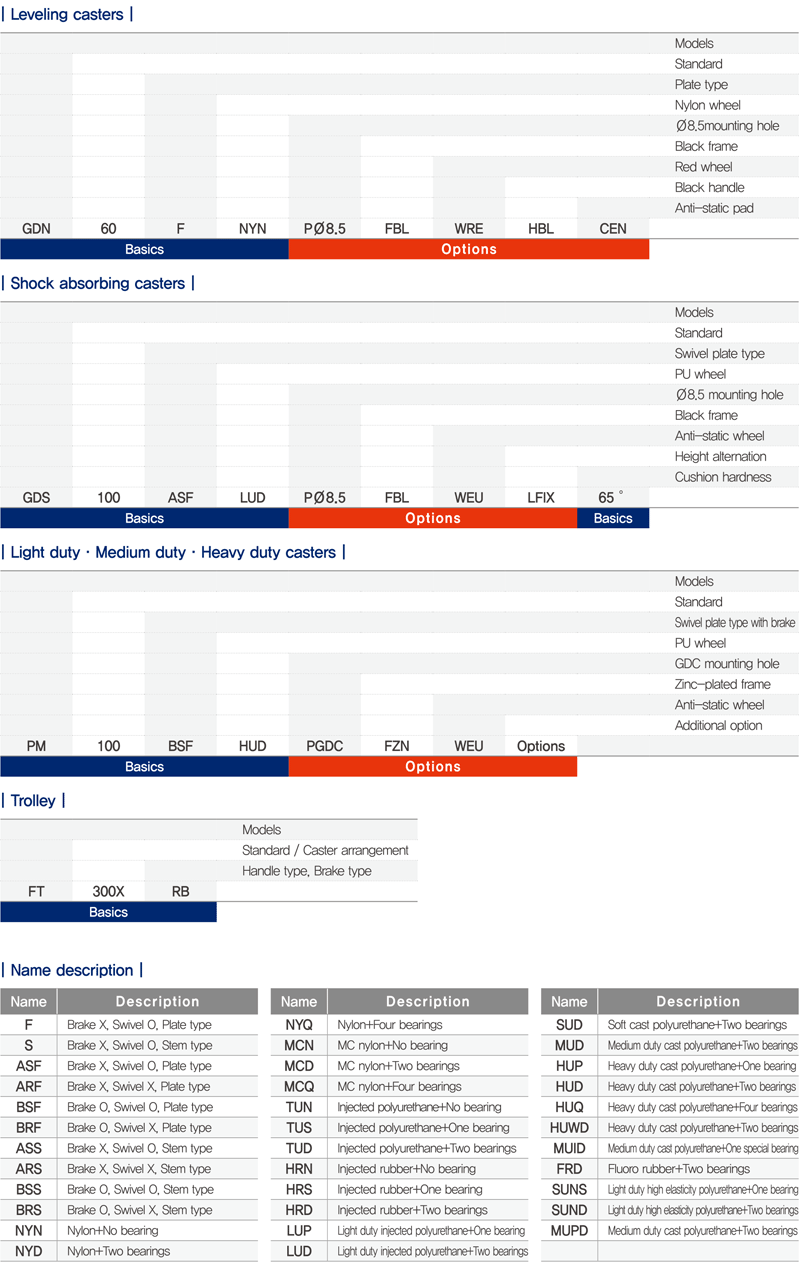

Leveling casters - GDN series GD-40, GD-60, GD-80, GD-150

Shock-absorbing caster wheels - GDS series GDS-100, 125, 130, 150, 200

Light Duty Caster Wheels - PL Series PL-75, 100, 125

Heavy Duty Caster Wheels - PM Series PM-100, PM-130, PM-150

Heavy Duty Caster Wheels - GXT Series GXT-80, 100, 125, 150, 200

Do you still use low-grade stainless casters for battery and secondary cell production lines? Not only is it expensive, but the quality is poor... But there was no alternative? NO!!

Choose G-DOK's premium casters for the secondary battery industry!1. Hazardous material removal for the battery industry only

2. Quality assurance through test report

3. 50% cost reduction compared to stainless casters